Category

Rotary Broach Tool HSS-Co Push Broach Pump Ring Broach

Our products are able to process various materials whatever are micro-thin, super-long, super-thin, super-wear-resistant

Basic Info

| Origin | Shanghai |

Product Description

| Why Choose Us |

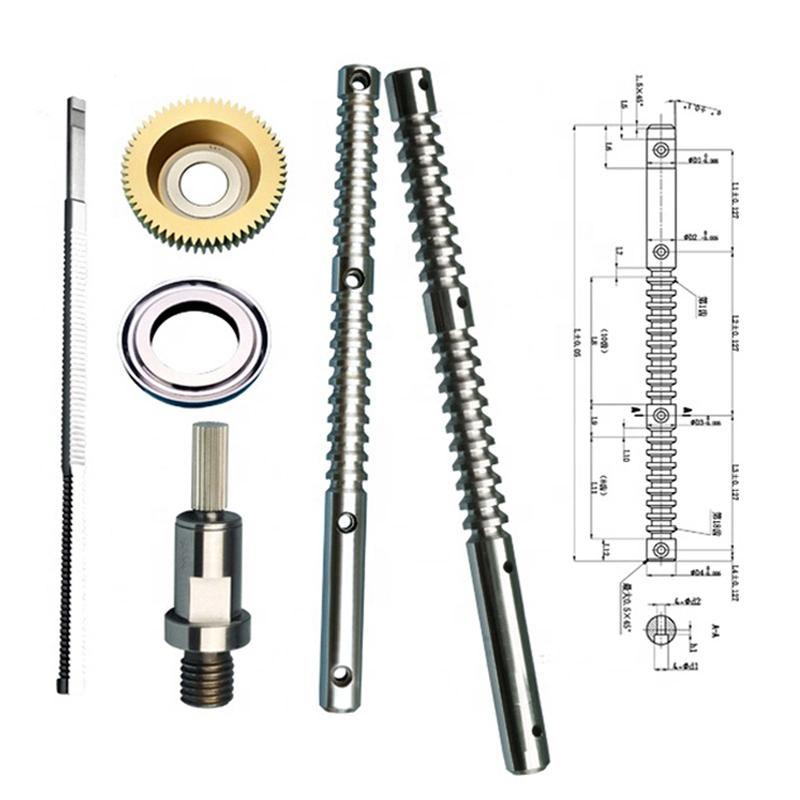

| Product name | rotary broach tool HSS-Co push broach Pump Ring Broach |

| Material | carbide/hard alloy/high speed steel/cobalt high speed steel/stainless steel |

| Size | OEM customize any size |

| length | customize |

| diameter | customize |

| Coating | we can coat according to your any requirement |

| Packaging | 1pcs/box |

| More Details | More information about our products in stock,please visit LZQ's official website: lzqtools com |

| Product Description |

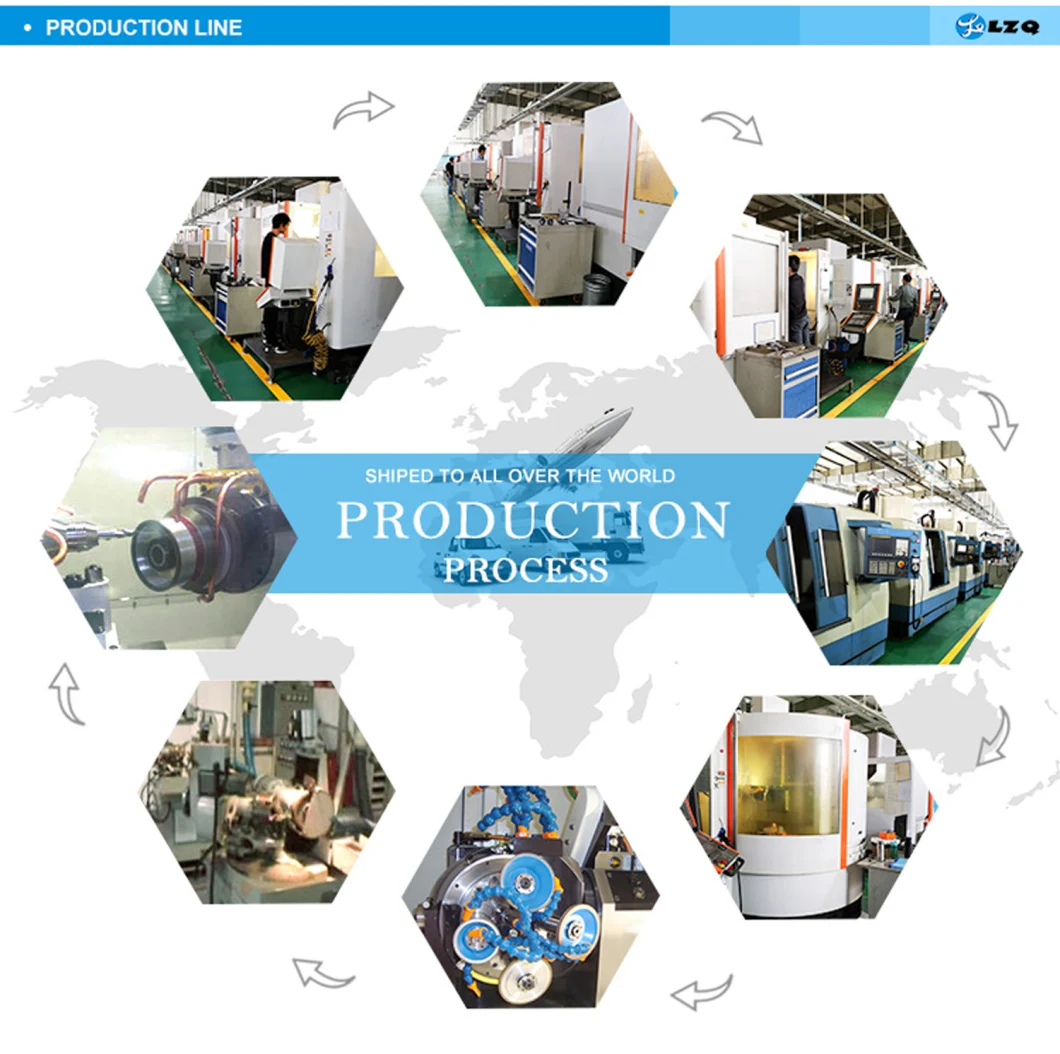

| Production Line |

| Company Information |

LZQ is a high-tech joint venture in the light of China's Rejuvenation, Great Harmony, Propagating health, Joyance & Sunshine... LZQ has been accumulating over 20 years of R&D experience in export-oriented medium and high-end CNC precision cutting tool, profile fixture, brazing fixtures, wear-resistant parts, high-precision accessories, super-high rust-proof & high hardness stainless steel high precision parts. Adhering to the advanced comprehensive production system, LZQ possesses various precision technology production and processing capabilities. We have introduced world first-class CNC equipment, powerful high-speed compound grinding machining center and best ultra-super-fine particle high quality raw materials, high-precision (3DX technology) molding superhard & Superfine grinding. We can achieve perfect edge quality and size tolerance up to +/- 0.0005mm (+/- 0.5micron) in fine, ultra-long, ultra-thin, ultra-abrasive, high-impact, highly complex and combined molding processing, which can realize high-efficiency and low-cost applications! We keep annual inventory of raw materials, semi-finished products and finished products amount to 30 million~40 million RMB turnover. We can produce according to drawings or samples with a fast delivery , also a very good cost performance... Joint supply and sales for medium and large enterprises, OEM assistance service for medium and large capitalization wholesaling. From high-end products processed by 6-axis / 7-axis linkage CNC (AAA grade), to middle-end products processed by 3-axis / 4-axis CNC (D grade), different levels of quality and different price ... Our reliable products can replace the first-class products, and we are professional in mass production, high cost-effective R & D, production & processing, as well as design revision according to drawings or samples of special, non-standard, special-shaped & new products. We can reduce the comprehensive cost greatly! When you make inquiry, referencing to the page footer, please provide samples with best work performance, and specify the detailed requirements, material types, dimensional tolerances, drawings of finished and semi-finished products, equipment used or equipment value (to judge its rigidity and runout, etc), monthly consumed qty, type of original samples and its inadequacies, the workpiece material to be processed by sample and its hardness HRC? ... Any deficiencies, please do not hesitate to let us know: Is it easy to get passivated? Or tipping? Or something else? Please provide new and old samples--with the best working performance--for us to check and test.