Category

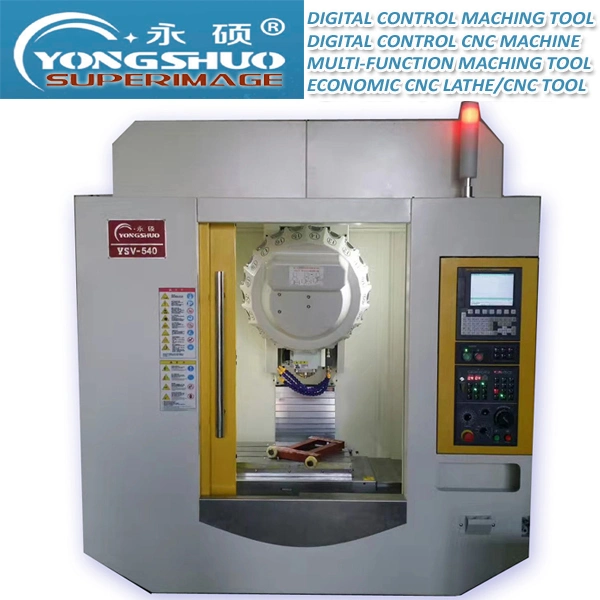

800*420mm Vertical CNC Drilling & Milling Machine Center CNC Milling & Drilling Tool

SUPERIMAGE CNC MILLING MACHINING CENTER 740 CNC Milling Machine 740 Vertical CNC Milling Machine VMC-740 Vertical CNC Mi

Basic Info

| Model NO. | SI-YSV740 |

| Performance Classification | Economical CNC Machine Tools |

| Certification | GS, CE, RoHS, ISO 9001, SGS |

| Condition | New |

| Transport Package | Wood Case |

| Specification | XYZ: 700*400*350MM |

| Trademark | SuperImage |

| Origin | Made in China |

| HS Code | 8458911090 |

| Production Capacity | 1000set/Month |

Product Description

SUPERIMAGE CNC MILLING MACHINING CENTER740 CNC Milling Machine

740 Vertical CNC Milling Machine

VMC-740 Vertical CNC Milling Machine

VMC-740 Vertical CNC Lathe

VMC-740 Vertical CNC Milling & Drilling Machine Center

VMC-740 Vertical CNC Milling & Drilling Machine Tool

CNC Machining Center

CNC MachiningTool

Digital Control CNC Lathe

Digital Control CNC Maching Tools:

For cutting

For milling

For drilling

For engraving

For turning

....

Multi-function

High efficiency, High Quality, High Hardness, High Stability

Low cost, Low noise, Low consumable, Less money

Yongshuo CNC Machine Center:

High Precision, High Rigidity, High Stability, High Efficiency, Long Use Life

- SuperImage-Yongshuo CNC Machine Center Function List:

| Functions List | |

| F1 | Spindle Tapping Blowing Device |

| F2 | Spindle Surround Spraying Cooling System |

| F3 | Spindle Constant Temperature Oil Cooling System |

| F4 | Spindle Center Air-curtain Automatical Protection System |

| F5 | Automatically Centralized Lubrication System |

| F6 | Z-axis Balance of Pneumatic and Hydraulic Systems |

| F7 | Tools Cooling System (Water-cooled, Air-cooled) |

| F8 | Tools Tapping Air Pre-storage System |

| F9 | Air Pre-Filtering System for Tapping |

| F10 | Guide Rails Protection System |

| F11 | Dust-proof Device of Electric Box |

| F12 | Air Cooling System |

| F13 | Hydraulic Station System |

| F14 | Nitrogen Balance Cylinder |

| F15 | Automatic Tool Height Setter Function |

| F16 | 4-axis Pre-integrated Interface Funciton in Mitsubishi/Fanuc |

| F17 | 5-axis Pre-integrated Interface Funciton in Mitsubishi/Fanuc |

| F18 | Big Milling Tools Tapping ProtectionFunction |

| F19 | Work-pieces Automatic Centering Function |

| F20 | Program Memory and Breakpoint Continuous Transmission Function |

| F21 | Real-time Automatic Tracking and Display Function |

| F22 | Fast Feed Speed Regulation Function |

| F23 | Program Handwheel Simulation Function |

| F24 | Surface Acceleration Function |

| F25 | Spindle Data Dynamic Setting Function |

| F26 | Other functions can be added as per the request. |

2. Price Terms:

(1).For different hardware and software and function configuration, the price is different.Please email us for quotation and details.

(2). Delivery Time and Transport Method:

Delivery Time: 30 Days after receiving the down payment.

(3). Payment Method: By T/T via Bank

Down payment: 30% of total amount. Before delivery, 70% balance need to be paid.

(4). Quality Warranty:

In China Mainland, within 12 month, SuperImage is responsible for repairing and maintenance without charge. If users ask for a spot installation, maintenance, and repairs aboard, the business trip fares (usually tickets, hotels, and etc.) need to be calculated additionally.

(5). Advantages & basic using information of SuperImage CNC Milling Machine Tool:

1). Hand wheel Guidance Function: this function can guide equipment to run by operating the hand wheel during the new program test processing, which can avoid collision caused by incorrect procedures in a big scale.

- . Centralization Function: Work piece coordinate system can be automatically calculated, and the programs can be automatically written. No calculators and manual input steps are needed;

- . High Speed Ethernet Transmission: Convenient and fast; Easy to call programs and solve programs problem during running with the expanded 2G memory

- .Tools Alignment Instrument (Option): Automatic tool aligning processing, convenient and fast;

- .High-quality HT300 Castings: The whole machine adopts high-grade resin sand molding castings, treated by tempering, vibration and natural aging treatment, the internal stress in the casting was completely eliminated.

- .Ultra-wide Base: Provide the most stable loading support capacity; The base is equipped with the design of the base guide plate, which make cutting fluid never leak;

- . Top-quality C3 ball screws made in Taiwan: The top-quality C3 grade ball screws made in Taiwan is used to ensure the accuracy of axial operation.

- .Top-quality precision P-level linear guide rails made in Taiwan and Germany: Ensure smooth and stable transmission;

- .Excellent telescopic shield: X,Y-axis rear shield adopts single-chip herringbone and full-Rail support to achieve effective protection and easy chip removal as well as easy to maintenance;

- .Top-quality Spindle made in Taiwan: P4 grade bearings are used to assemble the main body to ensure the low vibration of each running speeds.

- . Motors Dynamic Balance: Using Taiwan Dynamic Balance Instrument, the motor rotates at full speed to ensure that the motor reaches the minimum amplitude and extend tools life;

- . The accuracy of key parts of machine tools is measured by three-coordinate measuring instrument, and the important accuracy of machine tools before ex-factory is inspected and tested strictly by using the RENISHAW laser interferometer and spherical rod testers, which make the precision of CNC machining be able to be guaranteed completely.

A. Safety, Completeness and Reliability of Machine Tool Protection Device:

Complying with GB15760-1995 "General Technical Spare Parts for Safety Protection of Metal Cutting Machine Tools"

- Machine Tool Noise: 83 dB in accordance with the National Standard

- Cooling of electronic control cabinet adopts cold and heat exchanger to down the working temperature, sealed & dustproof; The dustproof grade reaches to IP65;

- Lubrication system: Mandatory lubrication of sliding surfaces and ball screws is adopted with automatic lubrication device; Adjustable oil injection interval and quantity; Machine display alarm when oil level is too low (oil shortage);

Lubrication box volume: 4 liters

- Cooling system:

Taiwan Luorui Cooling Pump, Motor Power 1HP

Cutting cooling for universal sprinkler spraying coolant;

- Pneumatic system air source requirements:

Pressure should be greater than 0.6 m Pa

Air cleanliness filtering accuracy: 100 um

Dryness Dew Point Temperature:10 ºC

Pneumatic system is equipped with three-point combination, pressure switch, solenoid valve and so on, to achieve pneumatic oil pressure loosening.

Knife pressure 6-8 kg/cm 2;

Flow rate 220 L/min, external air gun, which can clear the working area.

Fast pneumatic tools unloading device - supercharged cylinder is adopted.

- Tri-color warning lights:

Red light: display alarm

Yellow light: end of display program

- Machine Tool Power Supply:

Electric capacity of machine tools: 40 KVA

Air source: 6kg/cm2

Normal conditions of use:

Ambient temperature: 0-40 C / Humidity: <80%

- . The Description of Main Structure of SuperImage-Yongshuo CNC Milling Machining Tool;

- SuperImage-Yongshuo CNC Machine Workbench (X-axis)

- SuperImage-Yongshuo CNC Machine Saddle (Y-axis)

The Z-axis servo system adopts AC servo motor to drive the heavy load ball screw to rotate directly after speed reduction, and the double cylinder hydraulic balancing, so as to realize the high precision reciprocating motion of Z-axis. Lead screw support adopts fixed pre-stretching structure at both ends, which is rigid and suitable for heavy cutting.

- SuperImage-Yongshuo CNC Machine Column

The gantry structure with square double columns is adopted for the column. The frame has large cross section, strong rigidity and high accuracy retention, which meets the requirements of heavy cutting and finishing.

- SuperImage-Yongshuo CNC Machine Lubrication system

- SuperImage-Yongshuo CNC Machine Chip Removal Device

- SuperImage-Yongshuo CNC Machine Numerical control Unit

The system display uses 10.4"LCD color screen, standard Ethernet and PCMCIA input interface. The standard built-in program capacity is 256KB, and the expansion capacity is 2G. It can easily edit and transmit programs. It integrates convenient and efficient processing into a control system. The system built-in AI NANO function can be programmed 180 single sections, which can effectively resist the contour control of 3D processing and improve it. Shape accuracy.

The 64 bit RISC processor, AINO HPCC and DATA SERVO can be programmed in 600 single sections. It can be easily connected to high-speed and high-precision processing for all kinds of complex 3D curves to improve product output and production efficiency. Ladder diagram real-time monitoring page can bring convenience to maintenance.

- SuperImage-Yongshuo CNC Machine Spindle Unit

- SuperImage-Yongshuo CNC Machine Feeding System

This system owns easy adjustment with a good kinetic performance and high reliability.

- SuperImage-Yongshuo CNC Machine Electric Control Units

(7). About training:

After the contract is signed, the user can send someone to the seller's factory (SuperImag-Yongshuo) for the spot training for three days before the machine is in place. Participants in the training should have certain machine tool operation skills.

Training Contents:

- Operation, including:

- Introduction of Switching Procedure;

- Key Function of Operating Panel;

- Notice of Machine Tool Operation and so on;

- Programming, including:

G Instruction, M/S/T Instruction, Composition of Program;

- The instruction of the programming structure;

- The editing/storing/using of program and so on;

- Programming exercises.

- Maintenance, including:

- Key points of daily maintenance;

- General fault diagnosis methods;

- General Introduction of troubleshooting methods, maintenance exercises, etc

| TECHNICAL DATA | YSV-740 |

| WORKBENCH SIZE | 800*420MM |

| X-AXIS PROCESSING SIZE | 700MM |

| Y-AXIS PROCESSING SIZE | 400MM |

| Z-AXIS PROCESSING SIZE | 350MM |

| APPLICATION FIELD | Usually used for processing aluminum, flexible steel, copper, non-ferrous metal parts, alloy parts, plastic parts, gypsum parts, acrylic parts, dies, hand plates, etc. |

| SPINDLE(RPM) | 12000,15000,18000, 20000,25000 RPM ELECTRIC SPINDEL DIRECT CONNECT |

| SPINDLE MOTOR | 3.7KW-5.5KW |

| TOOLS MODEL | BT30 |

| CONTROL SYSTEM | FANUC,MITSUBISHI,SIEMENS,SYNTEC Four-axis function & five-axis function interfaces defaultly intergrated and built-in in system. Upgrade easily, Plug & play |

| WEIGHT MACHINE | 4000KG |