OEM ODM Customised Surface Anodizing Customized Machining Parts Auto Accessory

Basic Info

| Model NO. | BLKS-07 |

| Application | Auto Parts |

| Machining | CNC Machining |

| Material | Aluminum Alloy |

| Surface Treatment | Surface Anodizing |

| Design | 3D |

| Casting Tolerance | +/-0.10mm |

| Material Inspection Report | Material Inspection Report |

| Dimension Report | Dimension Report |

| Standard | CE |

| Certification | CE, ISO 9001:2000 |

| MOQ | Customized |

| Produce | Casting |

| Color | Customized |

| QC Control | 100% QC |

| Size | Customized |

| Surface Treatmen | Drilling, Milling, Other Machining Service |

| Packing | Poly Bag + Inner Box + Carton |

| Capability | Output 100 Tons Per Month |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Dr |

| Thickness | Customized |

| Service | OEM ODM Customised |

| Drawing Format | STP Igs Dxf Pdf |

| Usage | Industry Parts, Auto Parts, etc |

| Method | Machinery,Construction ,Hardware, Auto |

| Manufacture | Factory Produce Directly |

| Transport Package | Sea Package |

| Specification | Customized |

| Trademark | BLKS |

| Origin | China |

| HS Code | 8708920000 |

| Production Capacity | 1000000t/Year |

Product Description

Precision high pressure casting aluminum alloy auto parts processingAluminum alloy die castings are widely used in making cars, car engine blocks, car wheels, car chassis, brake pedals, and electric tool accessories. The products are mainly used in automobile accessories, electronics, sports equipment, photographic equipment, fishing gear, lighting, and various electric tools.Castings are suitable for casting engine cylinder, clutch housing, rear axle housing, steering shaft housing,speed changer, high-pressure oil pump, brake disc, mining machinery, valves etc,those are deeply recognized and praised by domestic and foreign customers.

Aluminum castings are formed by pouring molten metal into molds that have been shaped by a pattern of the desired final product. Three common types of molding methods are used to produce castings: die casting, permanent mold casting, and sand casting.Our Product Progress:Aluminum sand castingGravity die casting Aluminum die casting.

What material is used for aluminum casting?Graphite molds and cores are often employed with aluminum centrifugal casting. This process forces metal into the mold and uses rapid chilling to produce a quality of casting not possible with other methods. These are the seven types of molds for aluminum casting most commonly used to produce aluminum castings.

Parameters of aluminum alloy castings

| Material | Sand casting&Gravity casting&Low pressure die casting |

| Process | Sand casting, Gravity casting, high pressure die casting, low pressure die casting and CNC Machining casting. |

| Designs | 1.As per the customer's drawings 2.As per the customer's samples |

| Equipment of Casting | 1.High pressure die casting machining: 125T/180T/250T/280T/500T/800T/1250T 2.Gravity casting machine: 5 production lines 3.Low pressure die casting machining: 1 production line 4.Sand casting machine: 6 production lines 5.Degassing equipment and opportunities to refine the material 6.Machining: 5Sets CNC Machines;3 sets Milling machines; 3 sets Turning machines; 10 sets drill and tap machines |

| Testing facility | spectrometer, tensile test machine, hardness test machine, CMM dimension report |

| Certificate | ISO9001:2008/Rosh/SGS |

| Standard | ASTM, DIN,JIS, EN, ISO, GB standards |

| Software | Pro/E,UG, Solidworks, Auto CAD, PDF |

| Precision machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

| Finished | Polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing. |

| Product | All kinds of aluminum casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on |

| Advantage | 1.With more than 20years experiencesin Aluminum casting; 2.Have four casting types; 3.Near Sea Port and Air Port; 4.Passed ISO9001:2008/Rosh/SGS 5.From Casting to Finished surface, Owned casting, polishing and plating workshops, We can offer Good quality and strict delivery time. 6.With samples and order: We can offer dimension report, Chemical composition and Mechanical properties 7.Control material with spectral and thermal analysis equipment (density and processing) 8.Spectral analysis of raw material and liquid melt, batch before casting. |

Aluminum alloy castings have been widely used in the production of some castings in various industries, with high productivity and good casting quality, which is very conducive to mechanized production

Forming process: gravity casting, shell mold casting, pressure casting

Surface treatment: surface anodizingAluminum alloy die castings have low density and high strength. Using aluminum alloy castings can reduce the weight of the structure. Aluminum alloy castings are widely used in the aviation industry, power machinery and transportation machinery manufacturing.

Our aluminum casting productsOur advantage:

1.Our company has professional engineering R & D department, mold department, stamping department, polishing department, quality inspection department, packaging department, sales department, after-sales department and other departments

2.our company has advanced and perfect precision casting supporting equipment, German spectrum analyzer and test equipment, metallographic microscope, 1200kN press and mechanical performance test equipment, multi-element analyzer, Richter hardness tester, helium pressure leak detector and other test equipment

3.We can design molds and produce casting products according to customers' requirements, samples and drawings, and make all kinds of rough parts and finished parts

4.we have matching production equipment, including rapid high-frequency melting furnace, resistance melting furnace, horizontal pouring machine, turnover pouring machine, low-pressure casting machine, quenching furnace, curing furnace, shot blasting machine, sand blasting machine, laser cutting machine, laser welding machine, ion cutting machine, CNC machining center, milling machine and other equipment.Our cast aluminum equipment:

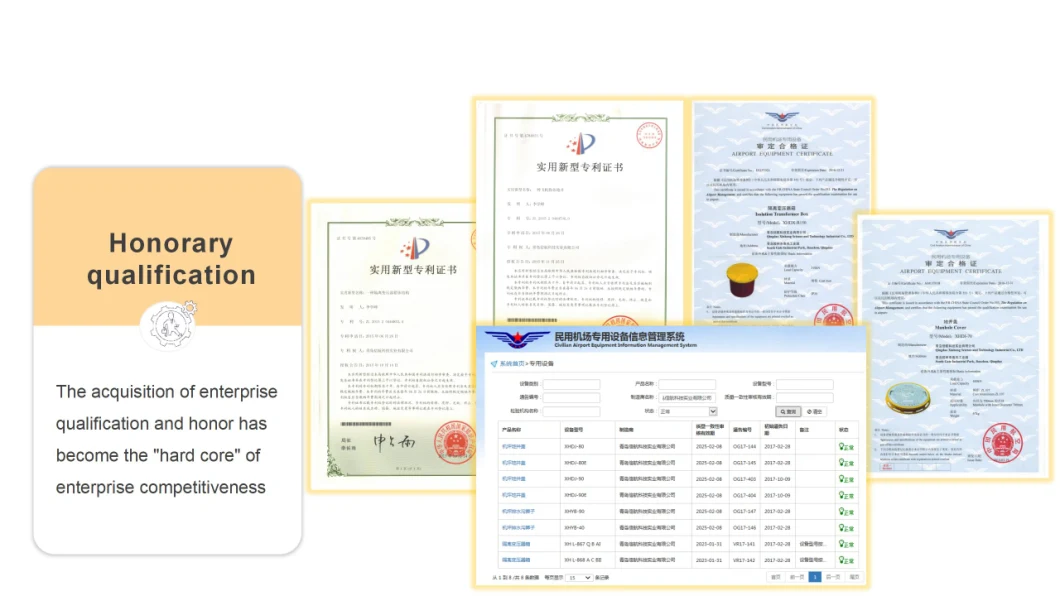

SHANDONG BOLAIKESEN UNMETAL TECHNOLOGY CO.,LTD is a casting enterprise integrating product design, production and sales, with an annual production capacity of 20000 tons.At present, mainly used silica gel precision casting process, coated sand casting process, gravity casting and die casting process etc,specializing in the production and processing of various metal castings such as stainless steel,carbon steel,cast iron and aluminum alloy etc,we are supplier of Civil Aviation Administration of China and Yuchai group.our products are sold to Japan, South Korea, Europe and the United States and many other countries.

Our partner

Q: Are you a factory or trading company?

A:We're a direct factory,we have our own casting foundry and machining factory over 20 years.

Q: Do you make customized products based on our design drawings?

A: Yes, we are a professional metal fabrication factory with 20 experiences to make custom products according to clients' drawings.

Q: Will my drawing be safe after you get it?

A: Yes, we will not release your design to third party unless with your permission.

Q: What is the MOQ?

A: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standard.

Q: Whether some samples can be provided?

A: Yes, just need some sample cost and express cost,we will provide some parts which we have stock.

Q: How fast can my samples be finished?

A: Generally 5-7 Working days