Category

Polished Tungsten Carbide Anti-Seismic Carbide Boring Bar

Feature of Tungsten Carbide Rod WC Grain size range: 0.3~0.5μ.m; 0.5~0.9μ.m; 1.0~1.3μ.m; 1.4~2.0μ.m.Diameter range: 0.33

Basic Info

| Model NO. | Carbide rod |

| Application | Aviation, Electronics, Industrial, Medical, Chemical, Metal Recycling Machine, Metal Cutting Machine, Metal Processing Machinery Parts, Metal Engraving Machinery, Metal Casting Machinery, Aerospace, Machining, Metallurgy, Oil Drilling, Mi |

| Standard | JIS, GB, DIN, BS, ASTM, AISI, API ISO Standard |

| Purity | Yg6 Yg8 Yg6X Yg11 Yg11c Yg13 Yg15 Yg15c Yg20 Yg20c |

| Alloy | Alloy |

| Shape | Oval, Square, Round, Rectangular, Lump, Customized |

| Type | Tungsten Carbide |

| Condition | New |

| Certification | ISO9001 |

| Customized | Customized |

| Material | Alloy |

| Warranty | 6 Month |

| After-Sales Service | 6 Month |

| Transport Package | as Customer Demand |

| Specification | 75/100/330mm or customized |

| Trademark | HONGZUAN |

| Origin | Hunan, China |

| HS Code | 8209101900 |

| Production Capacity | 20 Ton Per Month |

Product Description

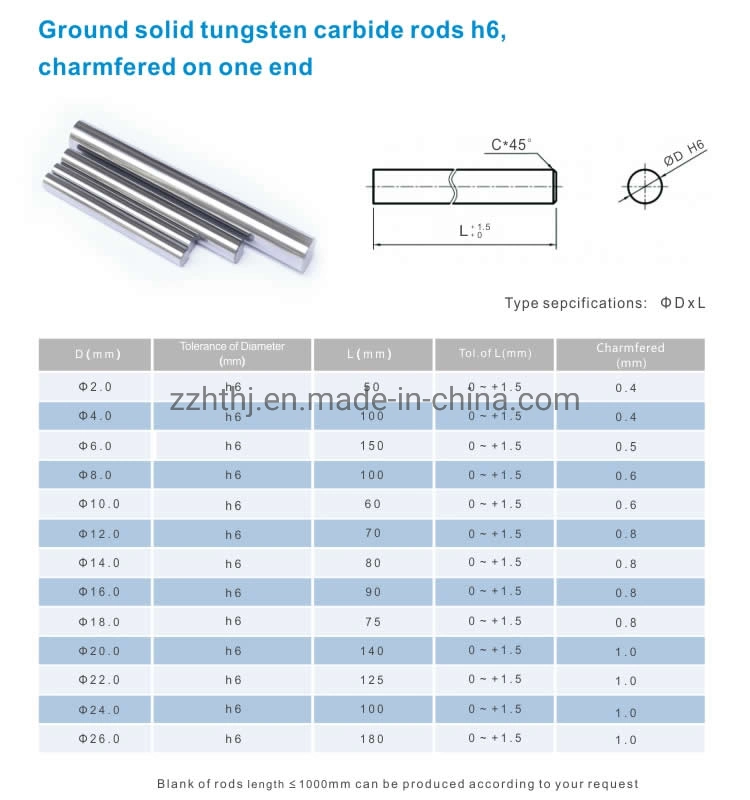

Feature of Tungsten Carbide RodWC Grain size range: 0.3~0.5μ.m; 0.5~0.9μ.m; 1.0~1.3μ.m; 1.4~2.0μ.m.Diameter range: 0.33mm--60mm;Length range: 3mm--700mm;Diameter Grade: h4(H4), h5(H5), h6(H6), h7(H7), h8(H8), h9(H9).Surface Roughness can be reached to: RA0.04.(reach a mirror effect surface after accurate grinding)Becides, We can understake order of non-standard size work.

Applications of Tungsten Carbide Rod

Solid tungsten carbide rods are used for cutting aluminum alloy, cast iron, stainless steel, refractory alloy steel, nickel-based alloy, titanium alloy, and nonferrous metals. Various carbide grades with stable properties have been widely recognized by worldwide makers of tools. Besides, solid tungsten carbide rods are widely used processed as HSS Cutting tool, carbide end mills, carbide cutting tool, NAS cutting tool, carbide end mill, aerospace cutting tool, carbide drill, high speed steel, milling cutter Core drill, tapered end mills, metric end mills, miniature end mills, pilot reamer, electronics cutter, step drill, metal cutting saw, double margin drill, gun barrel, angle milling cutter, carbide burrs, carbide tipped cutter.

For PCB drills, micro drills, end mills, and reamers, mold punches, core pins & hole drilling tools Submicron grade features in high wear resistance, toughness & combination abilities Good straightness, the roughness and surface roughness of finish ground rods are satisfactory. Advanced production technology, automatic pressing, HIP sintering, and precision grinding For your reference, I am enclosing a very frequently used grade for your reference.

All our solid tungsten carbide rods are made from extrusion method and HIP Sintered, with excellent quality and performances.

Grade for tungsten carbide rod

Grade/ Properties / Application | ||||||||

| Grade | ISO | Performance | Performance&application recommended | |||||

| Density | Bend Strength | Hardness | ||||||

| G/Cm 3 | N/mm 2 | HRA | ||||||

| YG6X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. | |||

| YG6A | K10 | 14.7-15.1 | ≥1580 | ≥91.0 | ||||

| YG6 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. | |||

| YG8 | K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. | |||

| YG10X | 14.5 | 2400 | 91.5 | Fine grain alloy, good wear resistance,Used for processing hard wood, veneer board,PCB,PVC and metals. | ||||

| YL10.2 | 14.5 | 2400 | 91.8 | Forming or stamping dies for metal powders and nonmental powders. | ||||

| YG13X | 14.3 | 2600 | 89.5 | For oil cone dril bits, for medium soft and medium-hard rocks. | ||||

Photos

Company ProfileZhuZhou HongTong Tungsten Carbide,specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications. Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc . We have a professional QC team follow to the System of ISO9001:2015, Covering the Raw Materials Incoming, Production Processes,Finished Products and Packaging to ensure high quality products output.

We mainly produce Tungsten Carbide Ball and Seat, Agriculture wear parts plates, Carbide tips, Carbide tiles,HPGR Stud pins, Brazed Inserts, Gripper Pads, Buttons, VSI Bars, Rod, Strips, PDC substrate, Weld on teeth,Bushings, Wire Drawing Dies, Heading Dies, Seal Ring, Nozzles, and other customized carbide products.

Product packaging

FAQ

Q1 : Are you Factory or trading company ?We are Factory with 20 years of production experience.Q2: What is the producing process?Production process including raw material cutting, machine processing, grinding, accessories cleaning, assemble, cleaning,stoving, oil coating, cover pressing, testing, package.Q3: How to control the products quality? All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.Q4: What is the transportation?If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.Q5: Can you provide OEM service?Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our productsQ6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our onlineInquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.Q7: What's your delivery time ?For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.Q8:How to contact us?You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on