Category

Vmc640 CNC High Speed Milling and Drilling Machine Tool for It Parts with Bt30 (T6)

Package size per unit product 1880.00cm * 2600.00cm * 2700.00cm Gross weight per unit product 3300.000kg Vmc640 CNC High

Basic Info

| Model NO. | T6 |

| Process Usage | Metal-Cutting CNC Machine Tools |

| Movement Method | Contour Control |

| Control Method | Closed-Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | Economical CNC Machine Tools |

| Certification | CE |

| Condition | New |

| Spindle Taper | Bt30 |

| Spindle Motor | 5.5kw |

| System | Syntec/Mitsubishi/Fanuc/Siemens |

| Max Load | 300kg |

| Name | CNC Drilling Tapping Machining Center |

| X/Y/Z Speed | 48/48/48 M/Min |

| Tool Alignment | Auto Tool Checking |

| Working Table | 700*400 |

| Precision | +-0.005/300mm |

| Repeat Precision | +-0.003mm |

| Power | 5.5kw 380V 3 Phase |

| Spindle Speed | 20000 Rpm |

| Max Working Speed | 10m/ Min |

| Applicable Industries | Machinery Repair Shops, Manufacturing Plant, Mold |

| Type | 3 Axis CNC Machine |

| Transport Package | Sea Worthy Plywood Case |

| Specification | 1880*2600*2700 |

| Trademark | WT |

| Origin | Dongguan City China Prc |

| HS Code | 8459619000 |

| Production Capacity | 2000PCS/Year |

Packaging & Delivery

Package size per unit product 1880.00cm * 2600.00cm * 2700.00cm Gross weight per unit product 3300.000kgProduct Description

Vmc640 CNC High Speed Milling and Drilling Machine Tool for It Parts with Bt30 (T6)

Product Description

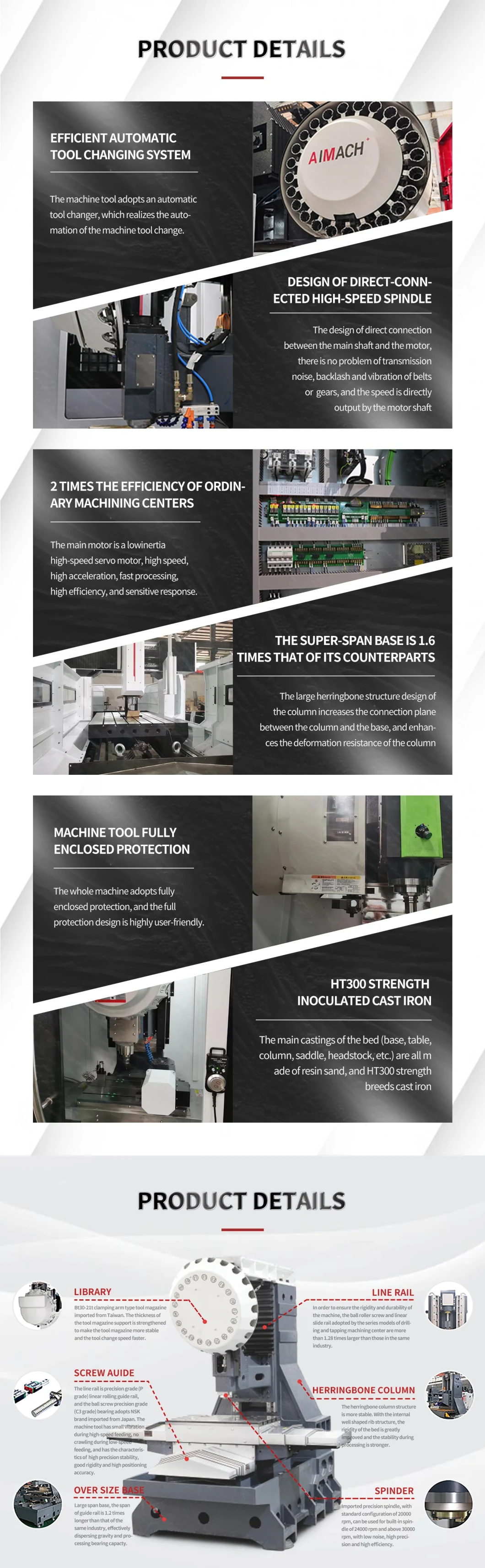

T640 is a high-speed drilling and tapping center machine tool, which adopts mechatronics design, beautiful appearance, and can be used for precision cutting. After the workpiece is clamped once, the machine tool can automatically and continuously complete the processing of various processes such as milling, drilling, boring, expanding, reaming, countersinking, and tapping. This machine is suitable for multi-variety processing of complex parts such as medium and small boxes, plates, discs, shells, etc. It is widely used in 3C products, IT equipment, optical equipment, medical equipment, and aluminum alloy products.

Product Paramenters

| Item | Unit | T-540 | T-640 | T-1065 | T-1365 | T-1600 |

| Journey | ||||||

| Three-axis travel (X/Y/Z) | mm | 500/400/300 | 600/400/300 | 1000/650/300 | 1300/650/300 | 1600/500/300 |

| Distance from spindle centerline to column guide surface | mm | 466 | 466 | 716 | 716 | 516 |

| Distance from spindle nose to work table | mm | 150-450 | 150-450 | 150-450 | 150-450 | 150-450 |

| Workbench | ||||||

| Table size (length X width) | mm | 650X400 | 700/400 | 1100X650 | 1400X650 | 1700X400 |

| Maximum load | kg | 300 | 300 | 450 | 450 | 450 |

| Number of T-slots X Slot Width X Spacing | 3X14X121 | 3X14X120 | 51X4X120 | 51X4X120 | 3/14/121 | |

| Spindle | ||||||

| Spindle speed | rpm | 20000 | 20000 | 20000 | 20000 | 20000 |

| Spindle taper hole | BT30 | BT30 | BT30 | BT30 | BT30 | |

| Spindle motor power | kw | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 |

| Speed | ||||||

| Rapid traverse speed (X/Y/Z axis) | m/min | 48/48/48 | 48/48/48 | 30/48/48 | 30/48/48 | 30/48/48 |

| Cutting feed rate | m/min | 10/10/10 | 10/10/10 | 10/10/10 | 10/10/10 | 10/10/10 |

| Tool magazine | ||||||

| Number of tools | pcs | 21 | 21 | 21 | 21 | 21 |

| Tool diameter/length/weight | Ф60mm/200mm/3kg | Ф60mm/200mm/3kg | Ф60mm/200mm/3kg | Ф60mm/200mm/3kg | Ф60mm/200mm/3kg | |

| The maximum diameter of the tool (full knife / adjacent empty knife) | mm | 60/80 | 60/80 | 60/80 | 60/80 | 60/80 |

| Machine tool accuracy | ||||||

| Positioning accuracy (X/Y/Z) | mm | 0.008 | 0.008 | 0.01 | 0.01 | 0.012 |

| Repeated positioning accuracy (X/Y/Z) | mm | 0.005 | 0.005 | 0.006 | 0.006 | 0.008 |

| Other | ||||||

| Air source/air pressure | 280L/min6-8bar | 280L/min6-8bar | 280L/min6-8bar | 280L/min6-8bar | 280L/min6-8bar | |

| Total capacity of machine tools | KVA | 15 | 15 | 15 | 15 | 15 |

| Tank volume | L | 160 | 160 | 220 | 220 | 230 |

| Machine tool dimensions (X/Y/Z) | mm | 1880X2600X2700 | 1880X2600X2700 | 2700/3220/2900 | 3300X3220X2900 | 3850X2680X2700 |

| Machine Weight (Approx.) | kg | 3200 | 3300 | 4000 | 4400 | 4100 |