Category

High Speed High Precision Rbt CNC Milling Drilling Tapping Center Machine Tools for Metal Cutting

High Speed High Precision RBT CNC Milling Drilling Tapping Center Machine Tools for Metal Cutting Parameters Machine Fea

Basic Info

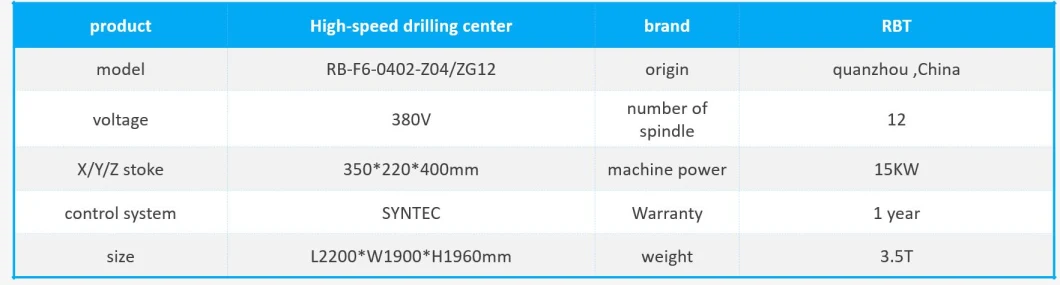

| Model NO. | RB-F6-0402-Z04/ZG12 |

| Layout | Vertical |

| Controlling Mode | CNC |

| Number of Shaft | 12 |

| Hole Diameter | 151-200mm |

| Automatic Grade | Automatic |

| Precision | High Precision |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Voltage | 380V |

| X Axis Effective Stroke | 350mm |

| Y Axis Effective Stroke | 220mm |

| Z Axis Effective Stroke | 400mm |

| Control System | Taiwan Syntec |

| Tool Library | 12 Spindle |

| Total Power | 15kw |

| Weight | 3.5t |

| Lubrication | Automatic Lubrication System |

| Chip Conveyor | Automatic Chip Conveyor |

| Lead Time | 15days |

| OEM | Machine Can Be Customized as Required |

| Y Axis Maximum Speed | 48m/Min |

| X/Z Axis Maximum Speed | 48m/Min |

| Frequency | 50Hz |

| Transport Package | Export Safety Packing (Customized Packing) |

| Specification | L2200*W1900*H1800mm |

| Trademark | RBT |

| Origin | Quanzhou, China |

| Production Capacity | 200set/Month |

Product Description

High Speed High Precision RBT CNC Milling Drilling Tapping Center Machine Tools for Metal Cutting

Parameters

Machine Feature

1. The overall stability of the machine is good, and the accuracy is stable and reliable.

2. Constant and high speed motorized spindle, high precision, good reliability.

3. Direct coupling connection, transmission rigid, high precision and stability.

4. Adopt timing and quantitative automatic centralized oil supply lubrication system to ensure that any lubricating part can be fully lubricated.

5. Taiwan SYNTEC CNC control system, humanized man-machine operation interface, safety specifications, convenient operation.

Application

Suitable for the drilling and tapping of the bathroom ware (eg. faucet), hardware, casting pieces, car accessory, lock, door knob, jewelry.

PACKING & DELIVERY1.Plastic film packaging and put in plywood wooden cases or according to customer's requirements.2.Shipping : Container transport.

FAQQ1. Where is your factory located ? How can I visit it ?A : Our factory is located in Quanzhou city,Fujian province,China. You can fly to Jinjiang or Xiamen air port, we will pick you up.Q2. Are you produce polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings. Usually one machine have different molds and fixtures like metal polishing machine,die casting machine.Q3. What is your sample service?

A: We can supply the sample testing which client want to produce or the spare parts. Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.Q6: How is your development ability?

A: We have a strong engineer team to support the drawing, technology proposal, test and certification; We can customize the machine per customer requirement. Q7: How about your after sales service?

A:We will arrange our technical staffs to your factory to install machine and teach you how to operate it. During the current special period, we will offer all support online via video 24h per day. Before shipment, we will test machine from and then send all videos from installation to production for customers. Full set of manual and instruction in English will be sent with machine together.