Category

Metal Auto Parts Milling, Drilling, Cutting CNC Machine Tools (VMC650)

Metal Auto Parts Milling, Drilling, Cutting CNC Machine Tools(VMC650)Features: VMC650 machining center configuration:1.

Basic Info

| Performance Classification | Economical CNC Machine Tools |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Transport Package | Plywood Shell |

| Specification | 2650x2300x2450 |

| Trademark | schuler |

| Origin | Shandong China |

| HS Code | 845710100 |

| Production Capacity | 200 Piece/Year |

Product Description

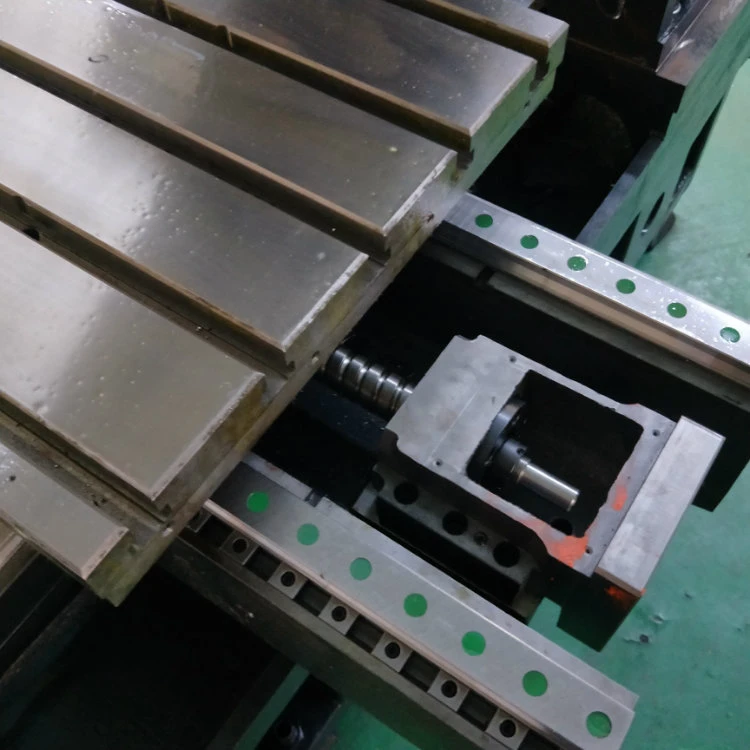

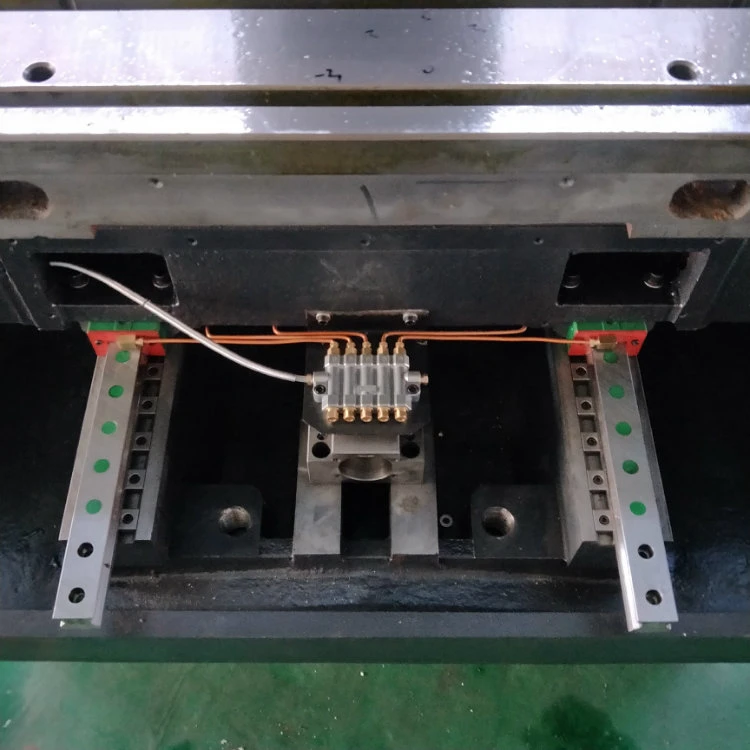

Metal Auto Parts Milling, Drilling, Cutting CNC Machine Tools(VMC650)Features:VMC650 machining center configuration:1. Resin sand castings.2. Taiwan's three-axis ball screw. (Taiwan silver)3. Precision lock nut. (Shanghai Yu Kai) (standard)4. Taiwan-made spindle, Japan NSK bearing, spindle pulley and belt. (Taiwan Health) 8000 rpm5. Taiwan-made pressurized cylinder. (Taiwan Hao Orange) (standard)6. Imported bearings (P4 grade). (standard)7. Domestic high quality coupling. (Tianjin Longchuang) (standard)8. Tool magazine 16 bucket knives (Tokyo, Taiwan)9. X, Y, Z (bottom) stainless steel rail protection. (standard)10. Imported electronic lubrication pump. (standard)11. Domestic cooling system water pump, water tank. (standard)12. Pneumatic components, . (standard)13. Headstock weight. (standard)14. System. Huazhong 808D, wide gsk990, Beijing KND2000M4,15. Machine alarm light (standard)The machine is equipped with an anti-impact device, which can absorb the vibration caused by the impact caused by the worker's operation error, so as to minimize the damage of the impact and ensure the original accuracy;The oil and water separation design can effectively separate the lubricating oil from the cutting fluid, and prevent the cutting fluid from deterioration, affecting the processing quality.

Brand Image:

As a professional manufacturer of milling machines, we want our customers to know of our commitment to providing the latest products to all customers.

| Model | VMC550 | VMC650 |

| Work table size | 700x350 mm | 900x400 mm |

| Max work table loading | 300 kg | 450 kg |

| X/Y/Z axis travel | 550x350x500 mm | 650x400x500 mm |

| Distance between spindle center and column surface | 419 mm | 476 mm |

| Distance between spindle and work table surface | 100-600 mm | 100-600 mm |

| X/Y/Z max feed speed | 10000 mm/min | 10000 mm/min |

| X/Y/Z max rapid speed | 20/20/15 m/min | 24/24/20 m/min |

| The spindle max speed | 8000 r/min | 8000 r/min |

| The spindle taper | BT40 | BT40 |

| Spindle motor | 3.7/5.5 kw | 5.5/7.5 kw |

| X/Y/Z axis Servo motor | 1.0/1.0/1.5 kw | 1.0/1.0/1.5 kw |

| T-slot of work table | 3-18x105 mm | 3-18x125 mm |

| Repeat positioning accuracy | +/-0.004 mm | +/-0.004 mm |

| Tool capacity | 12/16 | 16/16 |

| Max tool weight | 7 kg | 7 kg |

| Max tool length | 250/350 mm | 250/350 mm |

| Electric capacity | 8 | 10 |

| Machine size (L*W*H) | 2380x1950x2300 mm | 2300x2200x2400 mm |

| Net weight | 3200 kg | 4500 kg |

Agents Wanted:

We have strong partnerships in Europe, America, South America, India, Southeast Asia and South Africa. We also supply OEM service, and we are looking for agents in these areas. In the further, we want to develop SCHULER to a global brand. Wherever you are from, we are looking forward to explore new market with you.

Delivery:

The delivery depends on different machines with different configurations. Please contact us to confirm it is in stock or not.

Payment:

We prefer to do 100% T/T (30% T/T in advance, 70% T/T before shipment)

If any questions pls feel free to contact me

Tel+8618663288651