High-End Quality CNC Machining Milling Drilling Milling Machine Tools

Basic Info

| Model NO. | BF-1170B |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Transport Package | Wooden Package |

| Specification | 3500× 3600× 3100 |

| Trademark | BAOFENG |

| Origin | China |

| HS Code | 84571010 |

| Production Capacity | 2000 Sets Per Year |

Product Description

Specification| Travel | X-axis | mm | 1100 |

| Y-axis | mm | 700 | |

| Z-axis | mm | 700 | |

| Spindle nose to table | mm | 110-810 | |

| Spindle center to column | mm | 735 | |

| Worktable | Table size | mm | 1300x650 |

| Maximum load on table | kg | 1300 | |

| Controller | Mitsubishi System | M80 | |

| Spindle | Driving type | Belt | |

| Spindle speed | rpm | 8000 | |

| Spindle taper and specifications | BT40 | ||

| Spindle motor power | kw | 15-10000rmp | |

| 3 axis motor | X/Y/ Z axis motor power | kw | 3.0/3.0/3.0 |

| X/Y/Z rapid feed | m/min | 15/15/12 | |

| Machine accuracy (X/Y/Z) | Positioning accuracy | mm | 0.005/300 |

| Repeat positioning accuracy | mm | 0.003/300 | |

| Machine | Dimension | mm | 3500x3600x3100 |

| Weight | Kg | 9000 |

Standard Accessories:

1) Controller System: Mitsubishi M802) Spindle Motor: 15KW-10000 8000 RPM+XYZ:3.0/3.0/3.02) Spindle:15/10000rpm/BT40/Belt-type4) Heat exchanger

5) Workpiece Blowing System

6) Spindle Oil Coolant

7) Auto Lubrication

8) Cooling system for work piece

9) Full Protection

10) Operation manual

11) Alarming light

12) Working light

13) Full Cover for guide ways

14) Basic installation sets

15) Tool and toolbox

Application

Strong rigidity and cutting force box way series

It can realize drilling, milling, boring, reaming and other machining processes. It is mainly used for rough machining of parts and molds with large quantity of material removal which is applied in rough machining of general machinery, metal parts, injection mold, casting steel mold, and complex parts in automotive, shipbuilding, power generation, electronics and other industries.

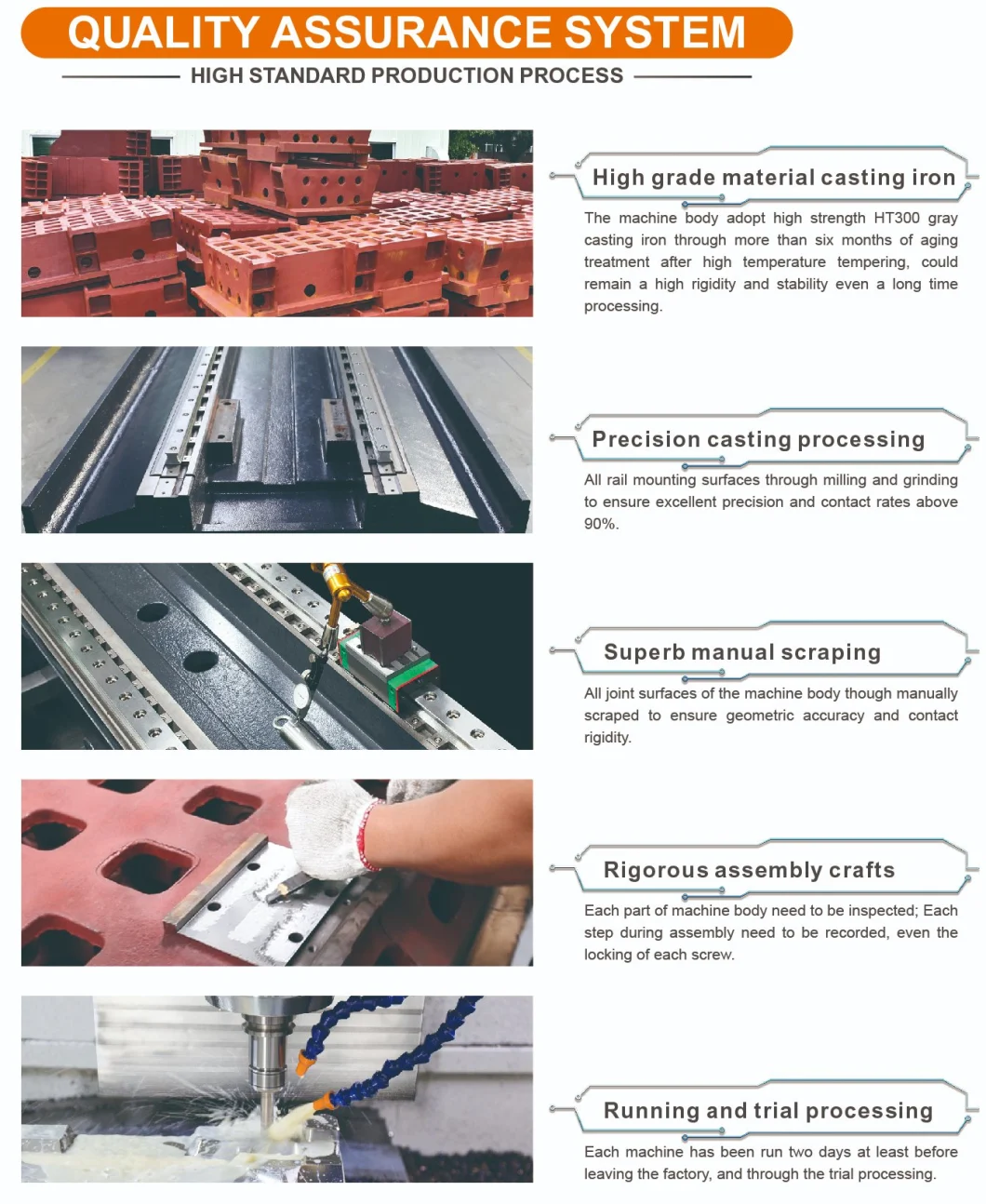

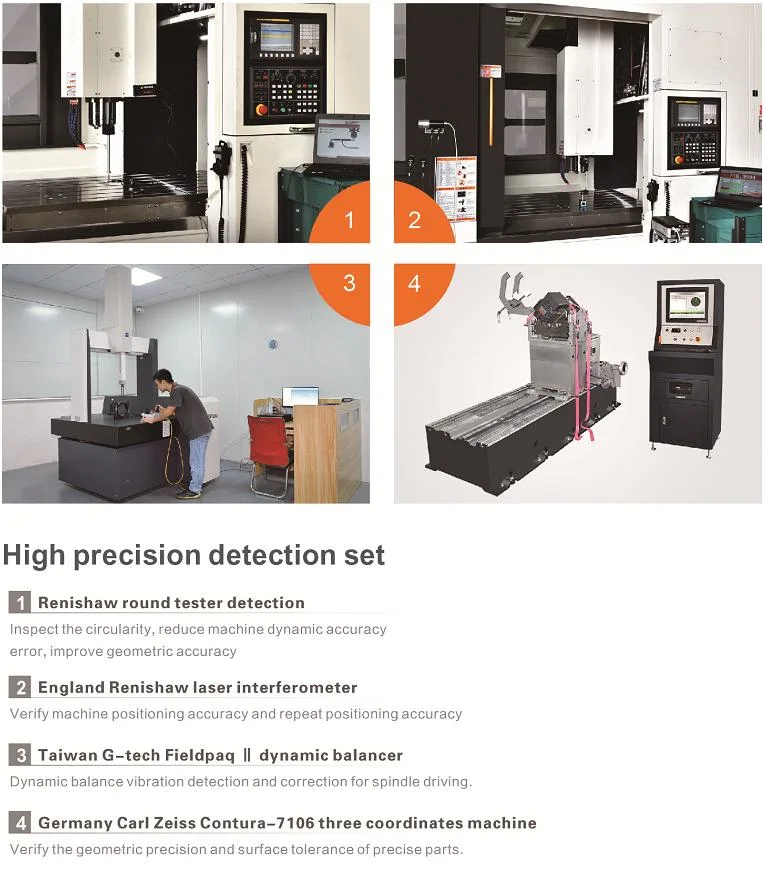

Quality Supervision

Company Profile

Dongguan Baoke Precision Machinery Co, Ltd is co-founded by Taiwan Baofeng and elites in Mainland China who engage in developing, manufacturing, selling, and service CNC machine centers. Our mainland manufacturing base is established in 2002, Baofeng has become a leading company for high-end machine center manufacturers in china as well as an integrated intelligent solution provider. We have 3 factories and we mainly produce various vertical machining centers (near guideway and square guideway), high-speed engraving and milling machine, double column machining center, and CNC tapping center. At present, Baofeng has a complete sales and after-sales service team across the country, but we try to bring our philosophy to the world and become a strong and competitive global player. We are now looking for partners overseas to build our dealer's network and at the same time prepare our local representative office.

Certificates ShowCase customer Packaging & ShippingFAQ1. How can I choose the most suitable machines?

A: Please tell me your specifications, we can choose the best model for you, or you can choose the exact model. You can also send us the products drawing, we will choose the most suitable machines for you. 2. What're the main products of your company?

A: We specialized in all kinds of machines, such as Vertical Machining Center, Double Column Machining Center, Drilling and Tapping CNC Machining Center, Engraving and Milling Center, etc. 3. Where is our factory located? How can I visit there?

A: Our factory is located in Dongguan City, Guangdong Province, China. You are warmly welcome to visit us. 4. What are your trade terms?

A: FOB, CFR, and CIF are all acceptable. 5. What are the Payment Terms?

A: Generally, T/T,30% initial payment when order,70% balance payment before shipment (This can be negotiated specifically); Irrevocable LC at sight. 6. What's the MOQ?

A: 1 set.